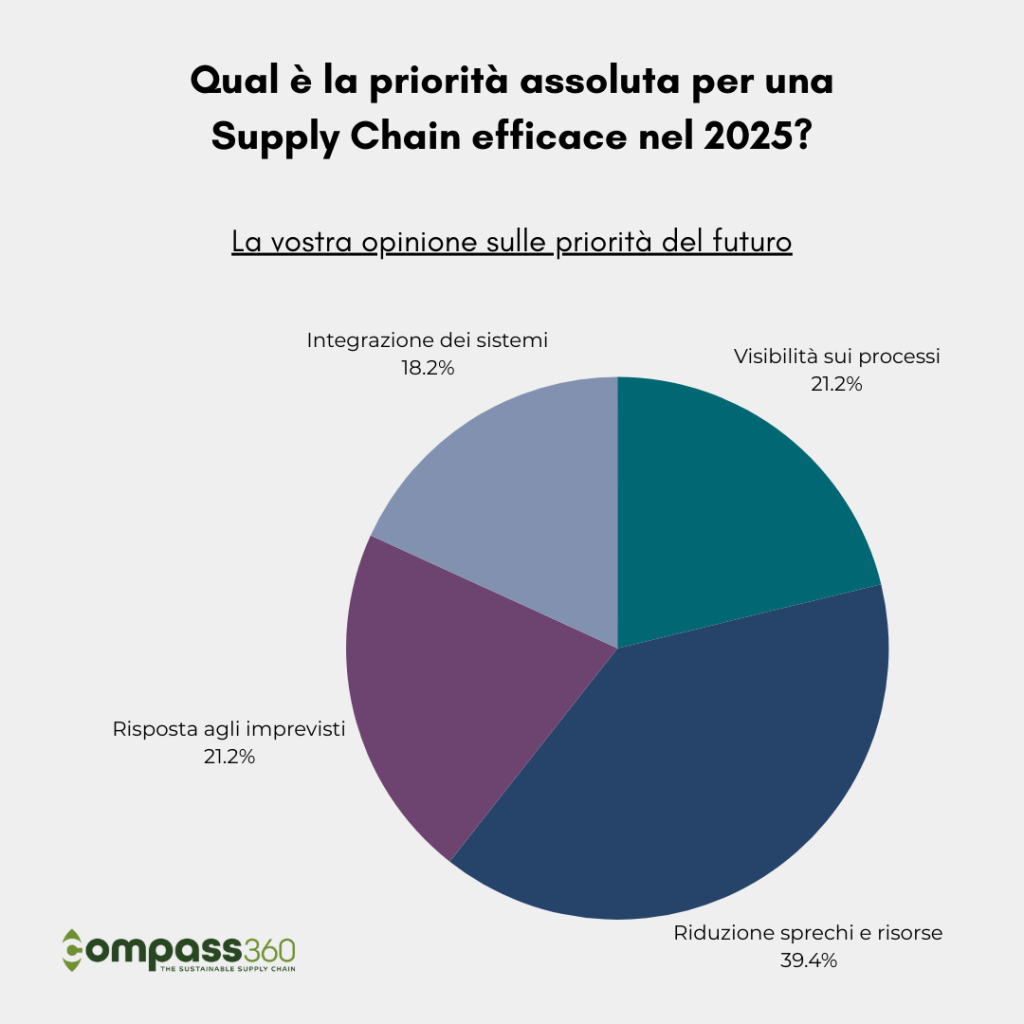

Recently, we launched a survey on LinkedIn to understand the top priorities for companies in Supply Chain management. The responses we received were highly insightful and provided valuable perspectives on a crucial topic: how to reduce waste and optimize resources in the Supply Chain.

The question we posed to our followers was:

“What is the main priority for the future of the Supply Chain?”

The results were clear and spoke for themselves: “Reducing waste and optimizing resources” received the highest number of responses.

This confirmed how sustainability and efficiency are increasingly crucial topics for companies that aim to be competitive while also acting responsibly in addressing the daily challenges of Supply Chain management.

But how can this need be translated into concrete actions? In a context where 94% of companies admit to lacking complete visibility into their Supply Chain (source: McKinsey), addressing these issues requires a strategic approach supported by advanced technologies.

Key Figures

- Up to 30% waste reduction can be achieved through predictive management and Supply Chain digitalization (source: Boston Consulting Group).

- 80% of companies that adopt automation and real-time monitoring solutions report significant improvements in operational efficiency (source: Deloitte).

- Only 6% of companies have end-to-end visibility of their supply chain (source: McKinsey), indicating a vast margin for improvement.

1. The Importance of Operational Optimization

Leveraging advanced technologies is essential to improve efficiency and reduce waste in the Supply Chain. Here are some key applications:

- Operational Data Analysis: Digital tools enable the collection and analysis of vast amounts of data to identify inefficiencies and optimize workflows.

- IoT Sensors: These provide real-time monitoring of resource status, promptly detecting anomalies that could compromise productivity.

➡ Practical Insight: The adoption of integrated platforms like Compass360 allows companies to gain a clear, real-time view of operational processes, optimizing resource utilization and ensuring leaner, more sustainable management.

2. Lean Processes

Adopting a “lean” mindset means minimizing activities that do not generate added value. When combined with advanced technologies, this approach can transform the way businesses operate.

➡ Concrete Example: A notable case is Florim, a leading company in high-end ceramic production. By implementing an integrated MES platform, Florim successfully optimized its production and warehouse management processes, reducing finished product inventory by 35% while maintaining high service levels.

3. The Role of Sustainability

A central aspect of waste reduction is sustainability. Today, companies must not only be efficient but also demonstrate a concrete commitment to environmental responsibility:

- Reducing CO2 emissions in logistics by optimizing transportation routes.

- Monitoring water and energy consumption to minimize waste.

➡ Interesting Fact: According to the World Economic Forum, the Supply Chain is responsible for 60% of global greenhouse gas emissions. Addressing this area of business can generate significant impacts.

4. Transparency and Collaboration in the Supply Chain

Transparency is key to eliminating inefficiencies. A transparent Supply Chain system enables:

- Improved trust between suppliers, customers, and partners.

- Waste reduction through better data sharing.

- Faster response to disruptions in the logistics chain.

➡ Practical Insight: Platforms like Compass360 provide real-time dashboards that connect all stakeholders in the Supply Chain, enhancing collaboration and reducing delays.

Conclusion

Reducing waste and optimizing resources is not just a challenge but also an opportunity to rethink business models in a more efficient and sustainable way. The combination of technological innovation, strategic mindset, and advanced tools like Compass360 can make a difference.

It is not just about eliminating what is unnecessary, but about creating value at every stage of the process.